Repairing DYJ Home985z Model

The DYJ Home985Z operates as a modular smart home automation system with integrated wireless connectivity. This model features a central hub that connects up to 32 different smart devices through Z-Wave Plus protocol.Key Components and Specifications

The DYJ Home985Z consists of five primary components:-

- Central Hub: 2.4GHz processor with 256MB RAM

-

- Motion Sensors: Three PIR sensors with 120-degree detection angle

-

- Smart Switches: Four programmable buttons with LED indicators

-

- Temperature Module: ±0.5°C accuracy range from -10°C to 50°C

-

- Network Bridge: Dual-band Wi-Fi (2.4GHz/5GHz) with ethernet port

| Component | Specification | Range |

|---|---|---|

| Power Input | 110-240V AC | 50/60Hz |

| Signal Range | Indoor | 30 meters |

| Battery Life | Sensors | 12 months |

| Memory | Internal Storage | 4GB |

Common Issues and Warning Signs

The DYJ Home985Z displays specific indicators when problems occur:-

- Red LED Flash: Network connection failure

-

- Yellow Blinking: Low battery in connected sensors

-

- Three Beeps: Hub firmware update required

-

- Green Strobe: Z-Wave network interference

-

- Silent Mode: System entering power-saving state

-

- Delayed response times over 3 seconds

-

- Inconsistent temperature readings

-

- Failed device pairing attempts

-

- Intermittent sensor notifications

-

- Mobile app synchronization errors

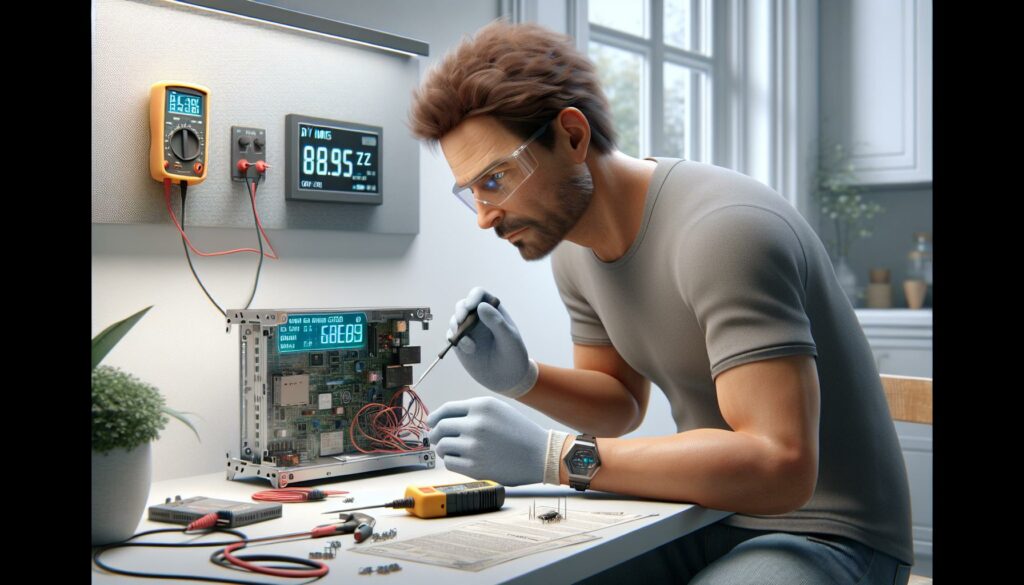

Essential Tools and Materials Needed

Safety Equipment Requirements

-

- Anti-static wrist strap to prevent electrical discharge damage

-

- Insulated gloves rated for 24V DC operations

-

- Safety glasses with side shields for protection during disassembly

-

- ESD-safe work mat measuring 24×36 inches

-

- Voltage tester rated for 3-24V DC circuits

-

- Proper ventilation system or fan for soldering tasks

-

- Phillips head screwdriver set (#00, #0, #1)

-

- Precision flathead screwdrivers (1.5mm, 2.0mm)

-

- Digital multimeter with continuity testing

-

- Soldering iron (15-30W) with lead-free solder

-

- Wire strippers for 18-24 AWG

-

- Needle-nose pliers with rubber grips

-

- Plastic pry tools for case removal

-

- Magnifying glass (3x-5x) with LED light

-

- Z-Wave frequency analyzer (433.92 MHz)

-

- Component cleaner spray (non-conductive)

| Tool Category | Specifications | Voltage Rating |

|---|---|---|

| Gloves | Nitrile-coated | 24V DC |

| Multimeter | Digital LCD | 0-50V DC |

| Soldering Iron | Temperature-controlled | 15-30W |

| ESD Protection | Anti-static equipment | 1MΩ-10MΩ |

Step-by-Step Diagnostic Process

The DYJ Home985Z diagnostic process follows a systematic approach to identify and isolate issues. This methodology enables users to pinpoint problems accurately through specific testing sequences and component verification.Testing Power and Connectivity

-

- Power Input Verification

-

- Measure input voltage at power port (12V DC ±0.5V)

-

- Check power adapter output using multimeter

-

- Inspect power cable for physical damage

-

- Test wall outlet with voltage tester

-

- Network Connectivity Tests

-

- Verify hub LED status indicators

-

- Ping device through network (response time <100ms)

-

- Check Z-Wave signal strength (-65dBm to -85dBm range)

-

- Confirm Wi-Fi connection stability (2.4GHz band)

-

- Device Communication

-

- Test device pairing functionality

-

- Monitor response time between hub and sensors

-

- Validate mobile app connection status

-

- Record network traffic patterns

-

- Circuit Board Inspection

-

- Examine PCB for visible damage

-

- Check capacitor condition (no bulging/leakage)

-

- Inspect solder joints for integrity

-

- Test fuse continuity

-

- Sensor Module Analysis

-

- Test motion sensor sensitivity

-

- Verify temperature module accuracy (±0.5°C)

-

- Check humidity sensor calibration

-

- Evaluate proximity detector function

-

- Memory and Processing

-

- Review system logs for errors

-

- Test RAM functionality

-

- Monitor CPU temperature (normal range: 40-65°C)

-

- Verify flash memory read/write operations

| Component | Normal Range | Warning Threshold |

|---|---|---|

| Input Voltage | 11.5V-12.5V | <11V or >13V |

| Signal Strength | -65dBm to -85dBm | < -90dBm |

| CPU Temperature | 40-65°C | >70°C |

| Response Time | <100ms | >250ms |

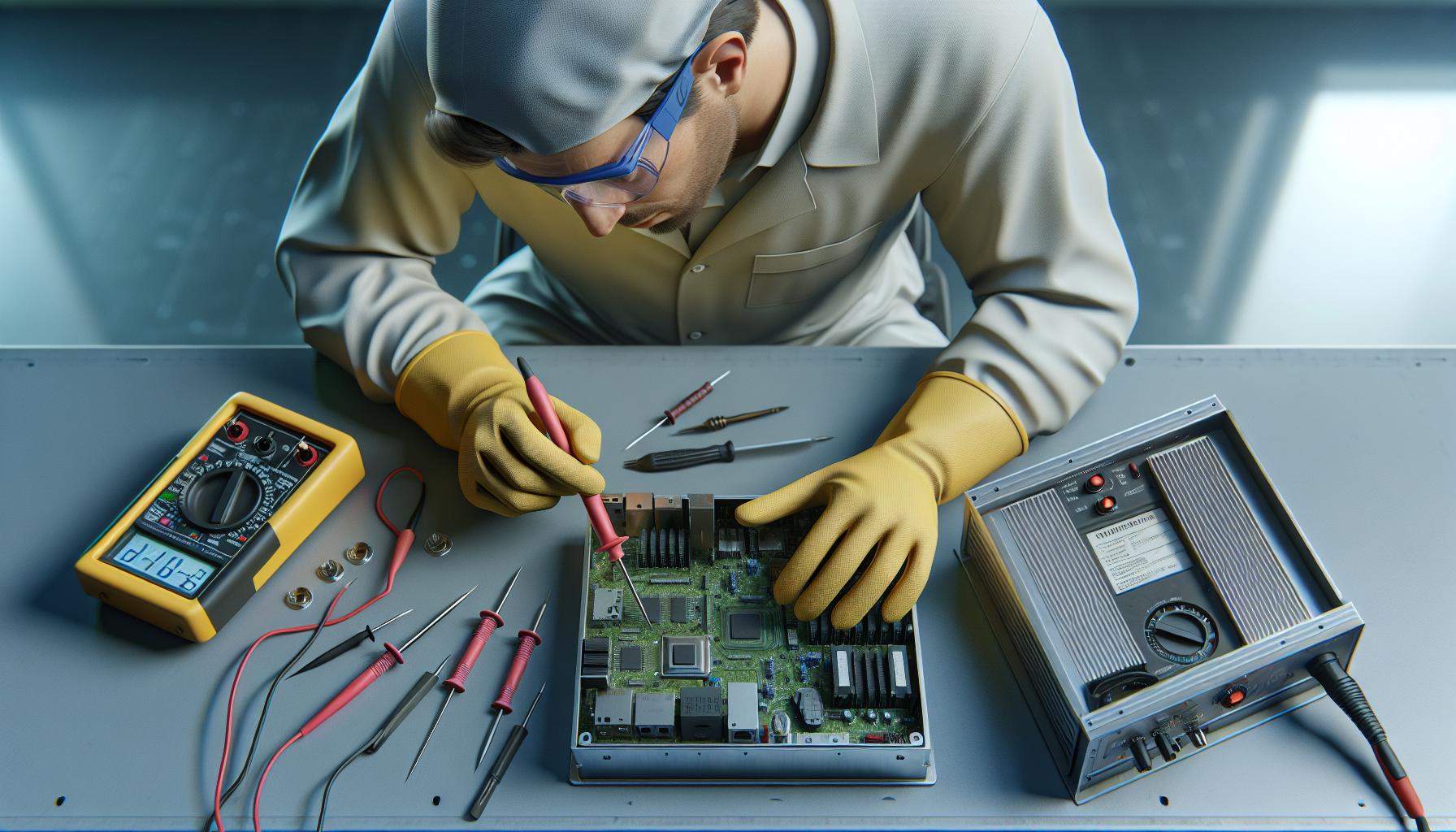

Main Repair Procedures

The DYJ Home985Z repair procedures focus on three critical components: circuit board maintenance, motor assembly replacement, and filter system upkeep. Each repair procedure requires specific techniques and safety protocols to ensure optimal system performance.Circuit Board Repairs

Circuit board repairs for the DYJ Home985Z involve addressing common electronic faults through systematic component replacement. The process starts with removing the 4 Phillips head screws securing the main board housing. Key repair steps include:-

- Inspecting solder joints at connection points R12 through R18

-

- Replacing damaged capacitors (C5 C8) with 470μF 16V equivalents

-

- Cleaning corrosion using 91% isopropyl alcohol

-

- Resoldering loose Z-Wave antenna connections at points A1 A2

-

- Testing voltage outputs at terminal blocks TB1 TB2 using a multimeter

Motor and Fan Replacement

Motor replacement focuses on the main drive unit located in compartment B of the device. The procedure requires:-

- Disconnecting the 12V power supply

-

- Removing the 6 mounting screws from the motor housing

-

- Detaching wire harness connectors MC1 MC2

-

- Installing new motor unit matching specs (12V DC 0.8A)

-

- Aligning fan blades with 0.5mm clearance

-

- Testing rotation speed (2400±100 RPM)

-

- Accessing the filter compartment via the side panel

-

- Removing particulate filters F1 F2

-

- Cleaning HEPA membrane with compressed air (max 30 PSI)

-

- Replacing carbon filter element CF3 every 3 months

-

- Verifying airflow sensor readings (200-250 CFM)

-

- Checking filter indicator LED functionality

-

- Testing system pressure differential (0.5-1.0 inWC)

Preventive Maintenance Tips

Regular maintenance extends the lifespan of the DYJ Home985Z system components while reducing repair frequency. These preventive measures optimize performance across all connected modules.Regular Cleaning Schedule

-

- Clean sensor surfaces with compressed air weekly to remove dust buildup

-

- Wipe the central hub’s ventilation ports monthly using a microfiber cloth

-

- Remove debris from motion sensors every 2 weeks using isopropyl alcohol

-

- Vacuum the internal components quarterly with an ESD-safe vacuum

-

- Clean the network bridge antenna contacts every 3 months

-

- Sanitize touch interfaces monthly with electronic-safe cleaning solutions

| Component | Cleaning Frequency | Method |

|---|---|---|

| Sensors | Weekly | Compressed air |

| Hub Ports | Monthly | Microfiber cloth |

| Motion Sensors | Bi-weekly | Isopropyl alcohol |

| Internal Parts | Quarterly | ESD-safe vacuum |

| Network Bridge | Quarterly | Contact cleaner |

| Touch Interfaces | Monthly | Electronic cleaner |

-

- Check power adapter connections every 30 days for loose fits or corrosion

-

- Test backup battery voltage levels quarterly using a multimeter

-

- Inspect Z-Wave antenna positions monthly for optimal signal strength

-

- Monitor LED indicators weekly for color changes indicating issues

-

- Examine circuit board components quarterly for signs of oxidation

-

- Verify temperature sensor accuracy monthly using a calibrated thermometer

| Component | Inspection Interval | Normal Range |

|---|---|---|

| Power Input | 30 days | 12V ±0.5V |

| Backup Battery | 90 days | 3.6-3.7V |

| Signal Strength | 30 days | -75 to -85 dBm |

| LED Status | 7 days | Green/Blue |

| Circuit Board | 90 days | No corrosion |

| Temperature | 30 days | ±0.5°C accuracy |

Troubleshooting After Repairs

Post-repair verification ensures the DYJ Home985Z functions optimally across all components. Testing identifies potential issues before regular operation resumes.Performance Testing

-

- Execute the built-in diagnostic program through the mobile app to verify system functionality

-

- Monitor response times between hub commands and device actions (optimal range: 0.5-2 seconds)

-

- Test signal strength between devices using the Z-Wave analyzer (minimum -85dBm required)

-

- Verify sensor accuracy:

-

- Motion detection range: 15-25 feet

-

- Temperature readings within ±0.5°F

-

- Light sensor sensitivity at 10-100 lux

-

- Check hub processing load (should maintain below 75% CPU usage)

-

- Confirm mobile app syncs within 5 seconds of system changes

-

- Measure voltage output from power supply (12V DC ±0.5V)

-

- Inspect electrical connections for secure fitting

-

- Test grounding points with multimeter for proper resistance (< 0.1 ohms)

-

- Verify safety features:

-

- Emergency shutdown response within 3 seconds

-

- Backup battery engagement during power loss

-

- Overcurrent protection triggers at 2.5A

-

- Monitor operating temperature:

-

- Hub: 30-85°F

-

- Sensors: 32-120°F

-

- Power components: Below 140°F

-

- Confirm all access panels are properly sealed

-

- Test backup communication channels through ethernet fallback